Sustainability

Our commitment

At Swire Coca-Cola, we’re deeply committed to environmental stewardship.

Join us in our journey towards a greener future. Together, we can make a meaningful change.

Our Sustainable Promise

Leading to a More Sustainable Future through our Production Lines

- Adopt Ultra-low Global Warming Potential (GWP) refrigerants

- Improve energy efficiency

- Reduce carbon footprint from cold drinks equipment

- Reduce material usage and packaging material

- Enhance circularity by only using colourless PET

- 39% Recycled Content for our PET bottles (excluding caps and labels) in Hong Kong SAR

- Reduce water footprint from our operations

- Improve efficiency on water usage

- Recycle treated wastewater back into our operations

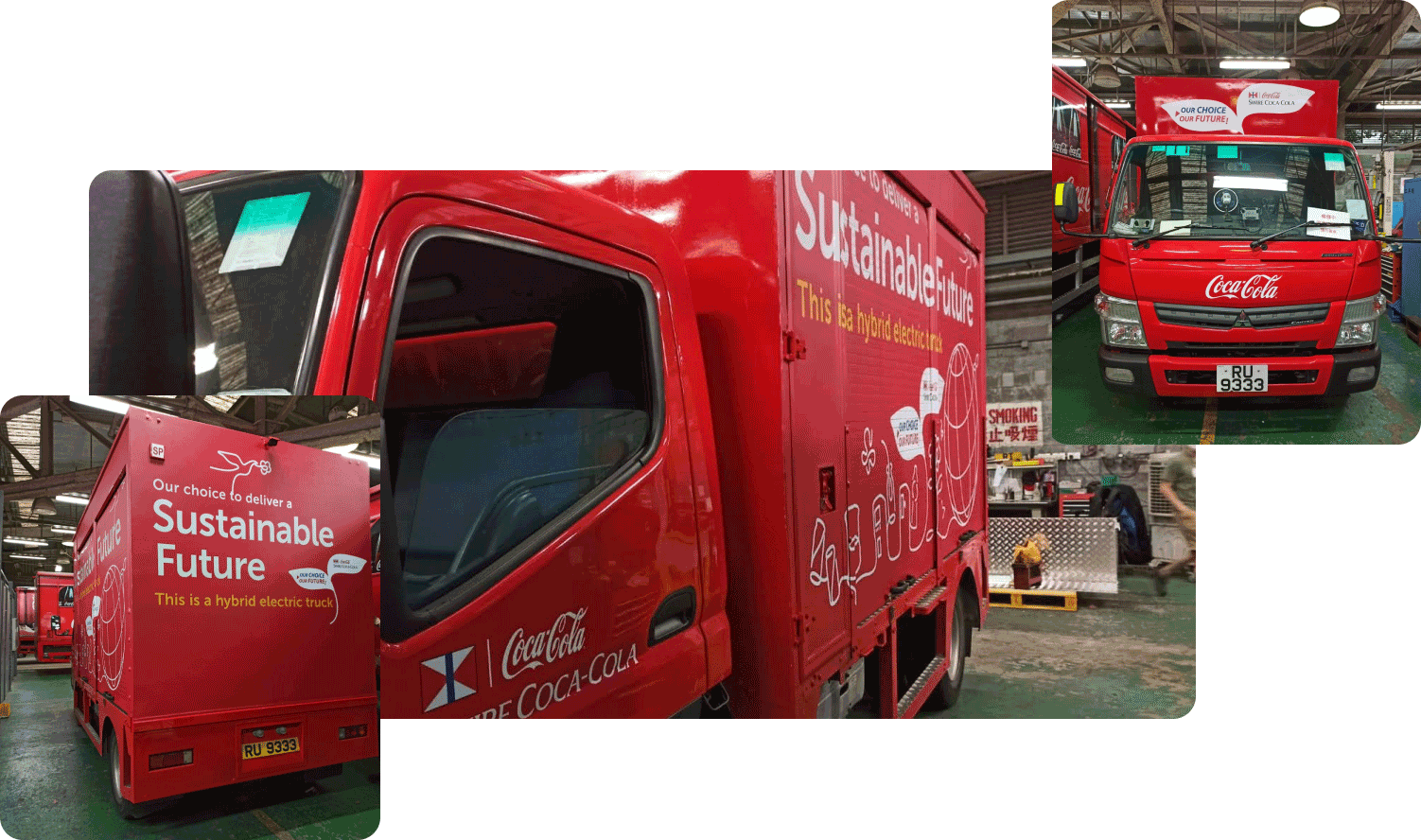

Decarbonising our Vehicle Fleet

Low Carbon Fleet

There is no silver bullet for decarbonising our fleet of 217 trucks, vans and cars in the Hong Kong SAR. Challenges include a lack of refueling infrastructure, long payback periods, and regulations restricting the speed at which the market can adopt new technologies. We have already deployed some electric vehicles and are looking into vehicles using renewable fuel source.

Since 2020, we require all new trucks purchased to be 100% “biodiesel ready”, even if road-going vehicles are not yet permitted to use blends higher than B7.

In 2022, we installed solar PV panels on five trucks to power air conditioning, the tailgate and some accessories. The main goal was to make the cabin more comfortable for our drivers and delivery crew while the vehicle is waiting, without switching on the engine. While the annual GHG emissions avoided are modest, every little bit counts!

Every project is an opportunity to engage our suppliers and people in sustainability.

Sustainable packaging initiatives

rPET

The first-ever Coca-Cola® Trademark packaging made from 100% rPET in Hong Kong.

As one of the largest Coca-Cola® bottlers in the world, SCCHK continues to leverage our expertise and develop new manufacturing technologies to offer consumers even more environmentally friendly beverage packaging choices that promote a circular economy. “Bottles Returned; Bottles Reborn.” Used PET bottles can be given a new life – again and again – if they are returned and recycled properly. Let’s join hands together to recycle the bottles and make a greener HK.